The machining of PA6 is in fact similar to the machining of materials made from metal alloys. In spite of the widely held opinion, the material can be shaped to a high degree of accuracy through machining processes such as turning, milling or drilling. This is due to the fact that during these processes, shape and structure stability are maintained due to the material’s structural properties. Parts made of Nylon 6 (PA6) are widely used in electrical engineering thanks to their properties. This is due to its electrical insulating properties and its relatively high heat resistance.

Properties of PA6.

Polyamid (PA6) is dimensionally stable enough to allow the creation of threads and lubrication grooves. This broadens its range of applications in various industries. In addition, its low coefficient of friction and high mechanical strength qualify the material for machining to produce components such as:

- washers,

- rings

- rollers,

- gears,

- sliding elements.

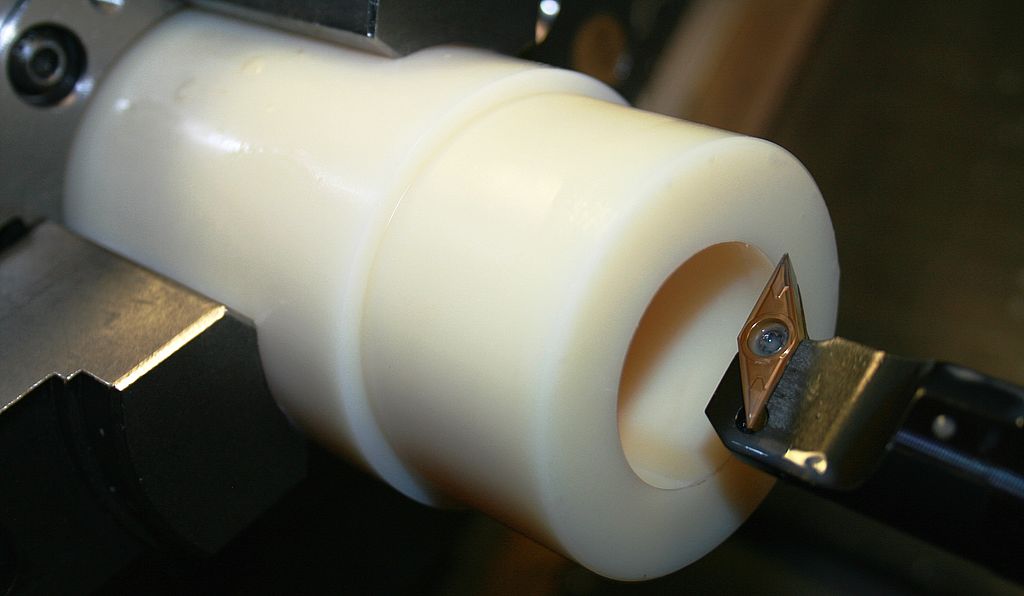

In production processes, polyamid is generally used to make bushings or sliding rolls with small cross-sections in the contact zones of the mating component. This is due to the relationship of the surface on which the loads act to the effective sliding speed. Consequently, the material should exhibit the greatest possible mechanical load resistance with the lowest possible wear during system operation. The sliding friction provided by this type of material is also dependent on other factors. The most important of these are the roughness of the interacting surfaces, as well as the lubrication method used. For example, for a bushing with a lubricating groove will be different, while one without this groove will be different. An important factor influencing the sliding friction of a component is the type of bearing material. An additional equally important advantage of the material is its wide operating range in temperatures from -60 deg C to 130 deg C. Resistance to petroleum-based substances (lubricants and others) and to chemicals used in maintenance processes is also important.

Processing of PA6 polyamid (Nylon 6).

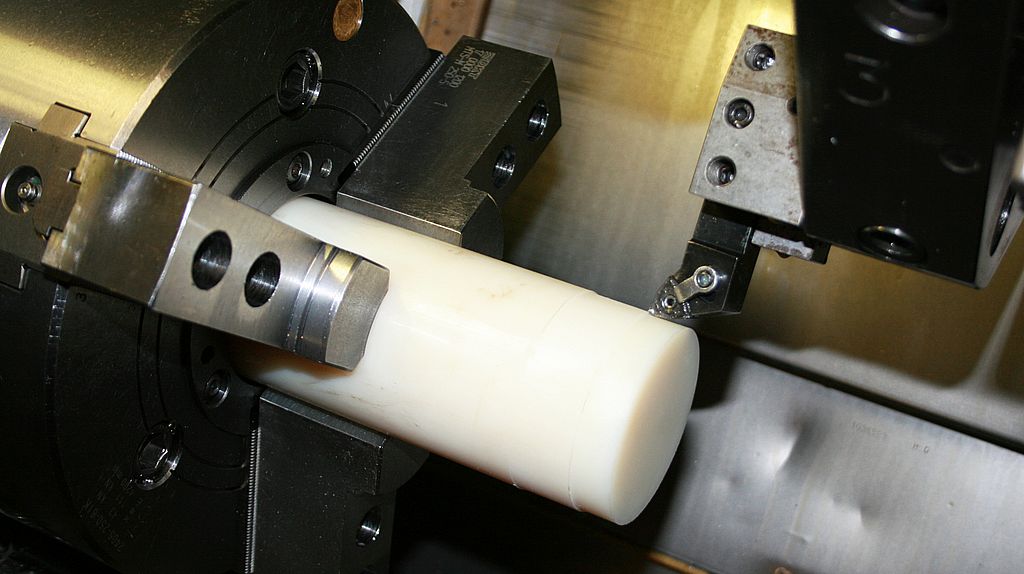

The production of components such as sliding sleeves begins with the preparation of the semi-finished product by cutting the material into appropriate sections at pre-set diameters. Then it is machined to the outside diameter. The next step is to drill the holes. Finally, the finishing of the geometry is carried out with all the details according to the technical documentation.

For more information and a full offer on the manufacture of Nylon 6 elements, please fill in the form opposite, or call our sales office: biuro@conmatec.pl.