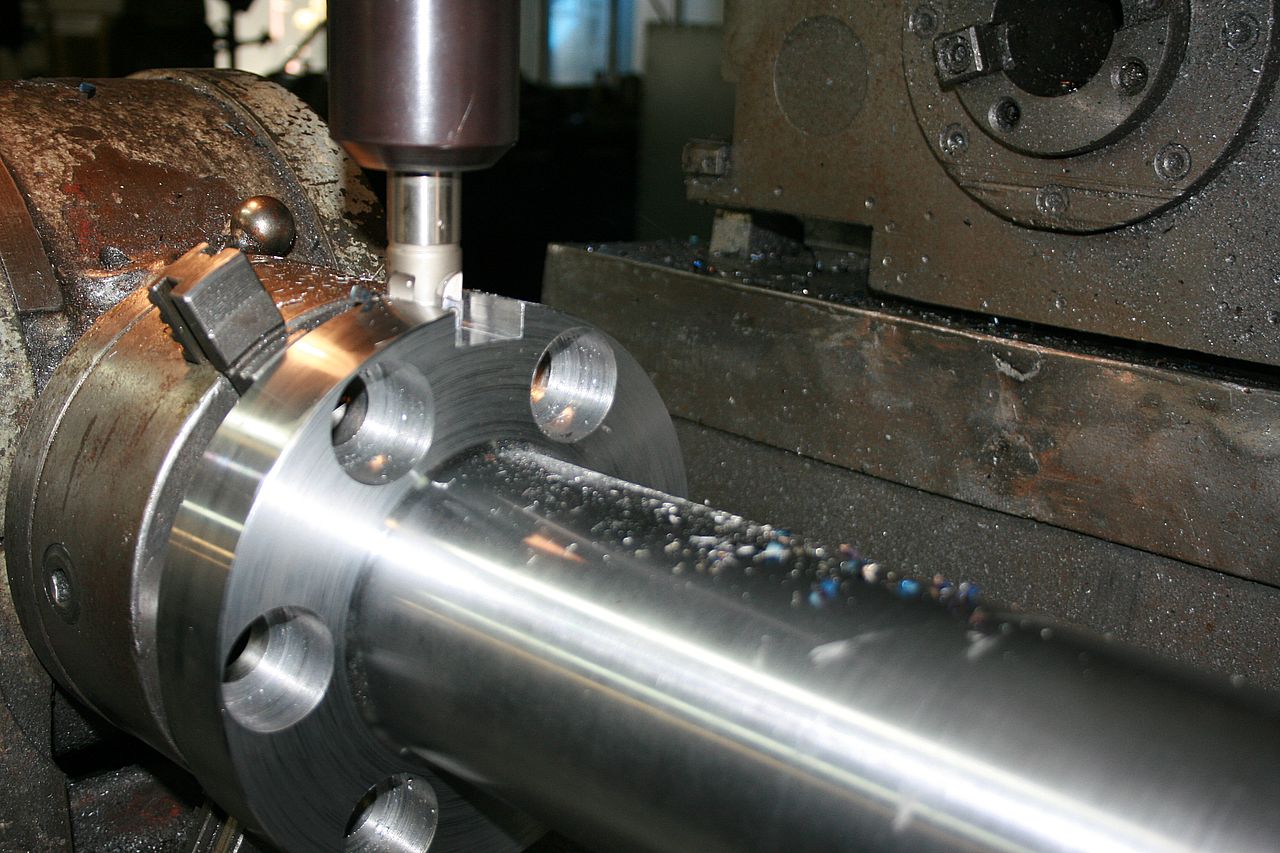

The production of drive shafts is characterized by the use of machining technology, in particular turning. In the production of shafts, it is possible to distinguish individual stages of the production cycle.

Production of propeller shafts – technological processes.

The first is the preparation process, in which we prepare the rough round bar from which the shaft will be made. It is important to choose the right diameter of the material and cut it on a band saw to lenghts taking into account the technological notifications. The next step is to make technological center holes if necessary. They are made to obtain material stability in turning centers and to plan allowances by turning. This operation belongs to roughing, which is characterized by a large cross-section of the machined layer and the highest possible feed rate.

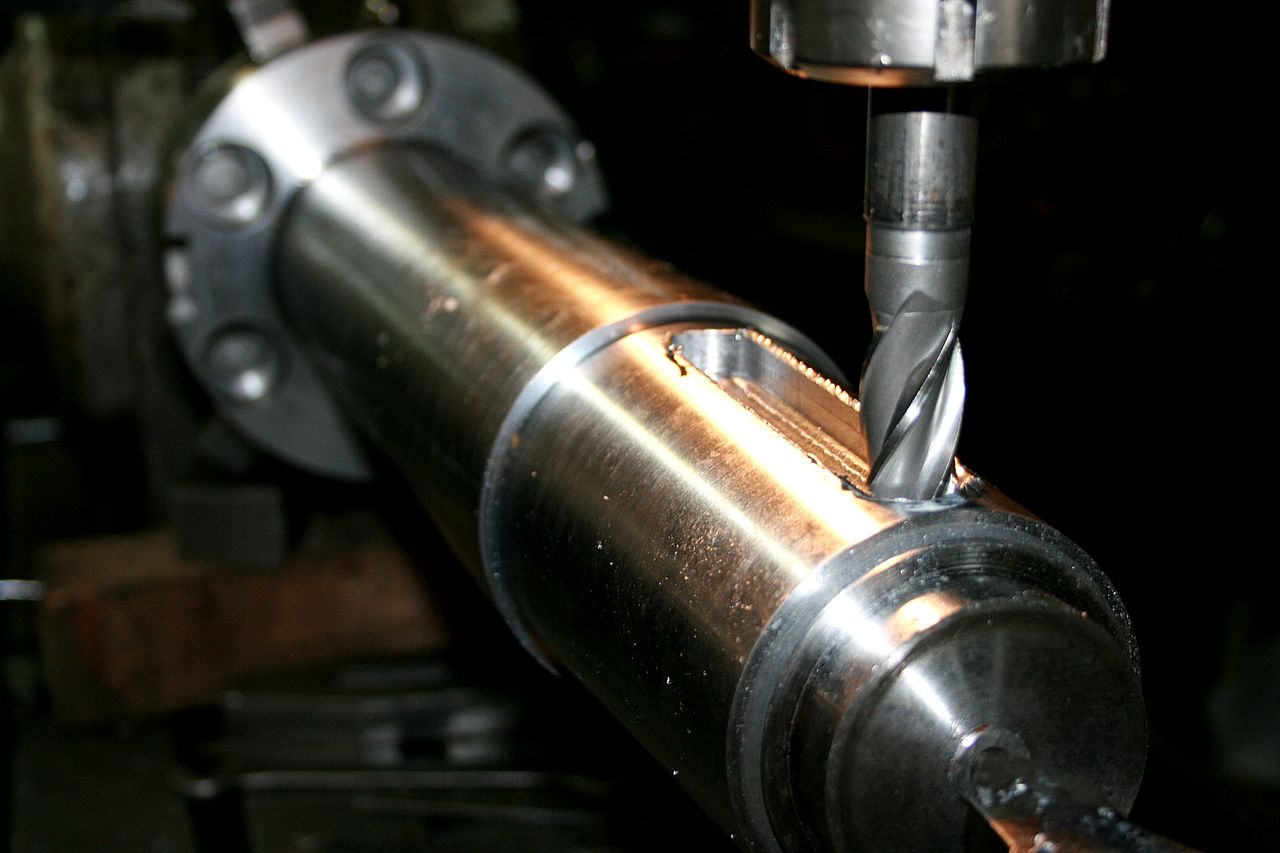

n the third stage, the production of drive shafts distinguishes operations to shape the shaft geometry, taking into account shape tolerances. For this purpose, tools with appropriate properties are selected for specific types of material from which the shaft is made. For drive shafts made of such steel as e.g. 40 HM or 34 HNM with mechanical properties much better than non-alloy structual steel, the feed range and cutting depth are selected from the range::

- ap – cutting depth 0.3-2.6 [mm];

- f0 – tool feed 0.1-0.25 [mm / rev].

It is also worth adding that the required surface roughness depends just on these parameters and the spindle speed. The last stage of the production cycle includes making cavities in the cylindrical shape obtained at milling centers or in the case of keys or teeth with a slotting machine. Sometimes the shafts are additionally subjected to a heat treatment process. This is to obtain better mechanical properties. This translates into one more phase: machining – finishing, in which the finishing allowance is removed after hardening.

The entire production cycle closes at the time of quality control and maintenance of the finished product obtained. We are able to deliver finished products to our clients anywhere in the European Union. We guarantee the highest quality of drive shafts manufactured in our factory.

We invite you to take advantage of our experience.