The end cup of the hydraulic cylinder is a structural element closely related to the cylinder mounting method. The layout of the hydraulic cylinder design is related to the end cup structure:

- When mounting through pins on self-aligning bearings, the end cup of the cylinder must be prepared for mounting the spherical bearing.

- For mounting on the rear flange – the end cup of the cylinder itself is also a flange or the mounting flange is integrated with the bottom of the actuator.

- In the case of mounting on the front flange and mounting on pivots or on feet, the end cup of the cylinder is not adapted to the function of mounting the cylinder and structurally it can only serve as a connection body for oil supply. It can also serve as a body for any valves for hydraulic cylinder.

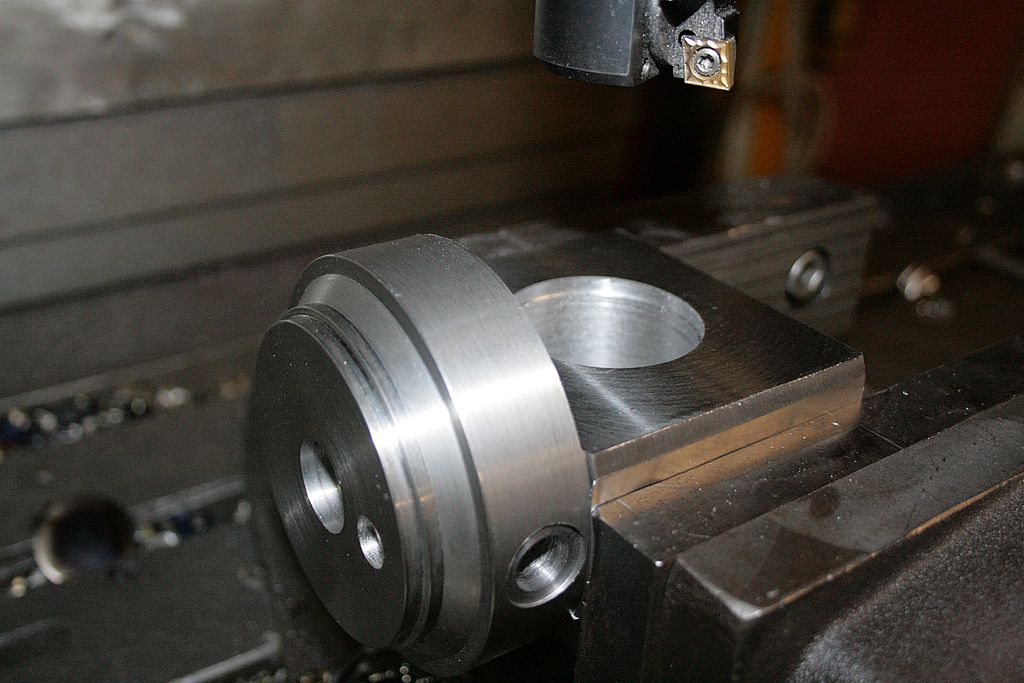

The end cup of the hydraulic cylinder during production.

The end cup of the hydraulic cylinder can be structurally adapted for welding with the cylinder body. In other cases it is adapted for mounting by screwing to the cylinder flange. The design of the hydraulic cylinder equipment requires appropriate solutions for both the guide bush and bottom of the cylinder. They are, for example:

- the use of a piston damping system;

- brake valves or valves having a braking function;

- use of logic valves as part of the cylinder movement control system or control of other system assemblies.

As a manufacturer of hydraulic components, we are able to carry out individual and short series production of special designs of the cylinder end cup structures with piston sizes D [mm]: 32, 40, 45, 50, 55, 63, 70, 80, 90, 100, 110, 125, 140 , 160, 180, 200.

We manufacture cylinder end cups from variety of materials. However, most often we use steel alloys for their production:

- S355 – most often for welded bottom cylinders;

- C45 or 42CrMo4 for cylinders with screw bottom.

Ready-made cylinder components.

We encourage you to contact our sales office to discuss the details of the production of parts for hydraulic cylinders. Individual elements or complete hydraulic cylinders are sent by forwarding companies to the place designated by the customer. We invite you to cooperation.